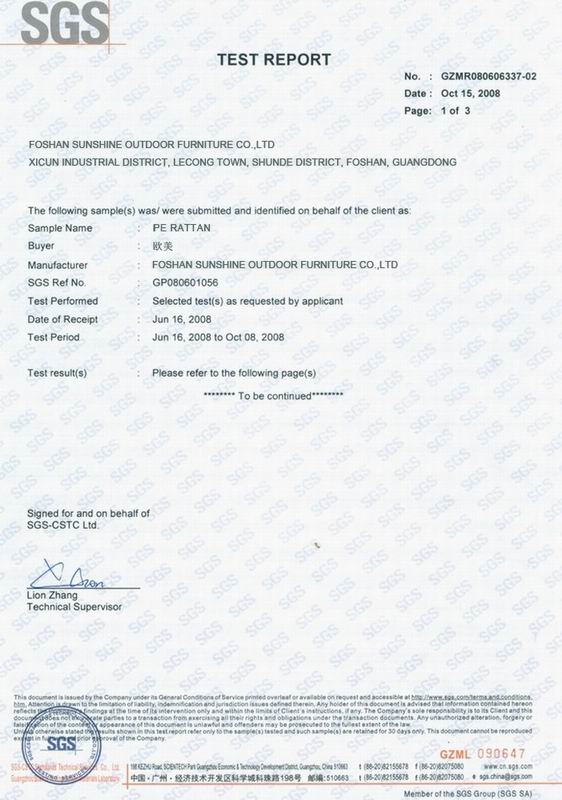

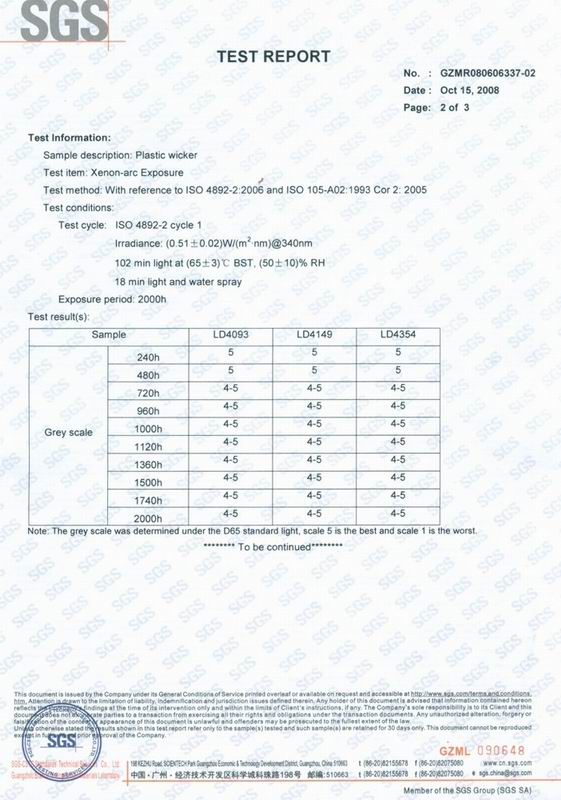

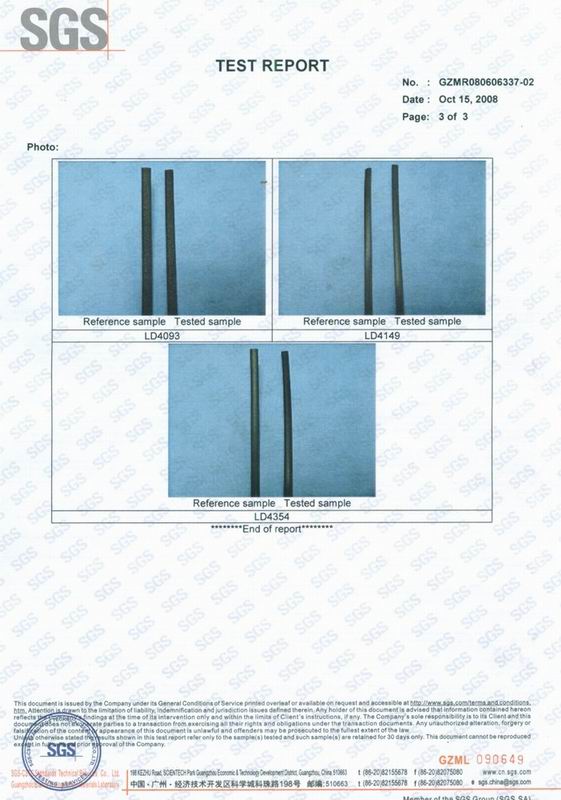

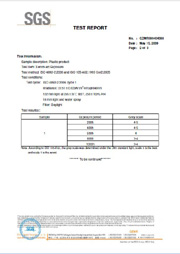

As a professional outdoor furniture manufacturer all of our material located in high standard .the rattan we use for our product is SGS Tested synthetic rattan, which is made from 99.8% Polyethylene .And 0.2% Ash.this rattan is good UV radiation,high temperature resistant, color fadeless,weather resistant. in line with ethical standards ,it is also non-toxic , eco friendly &100% recyclable.

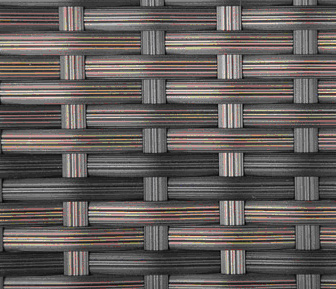

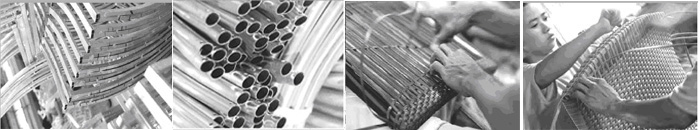

1.) Rattan: we use SGS Tested synthetic rattan, which is made from 99.8% Polyethylene and 0.2% Ash. This kind of rattan is UV resistant and waterproof .2 years of outdoor usage. (imported viro rattan available)

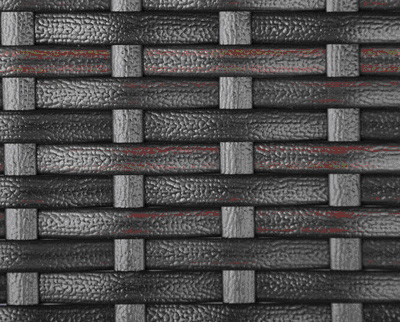

--Flat rattan: width of flat rattan:normally 7mm. The thickness of flat rattan we use is 1.4mm;

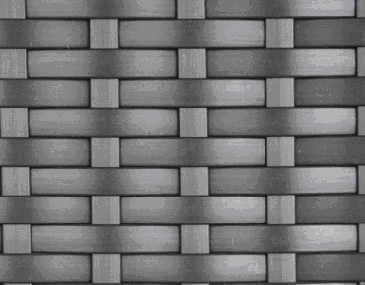

--Round rattan: Diameter is between 2.5mm to 2.8mm;

.jpg)

2) Structure : made by 1.2mm or 1.5mm thickness aluminum tube integrate powder-coated surface finish make the structure defile-resisting and antirust characteristic more stronger and stable than market.

3)Cushion:180g or 250g polyester,colours are optional. It is water-proof. thickness of cushion: for dinning chairs,normally we use 6cm or 8cm. but for sofa or lounge/bed, normally we use 10cm. But we can also make it according to customers' requirement; (imported Sunbrella available)

|

||||||||||||

| Polyethylene or polythene (IUPAC name polyethene or poly (methylene)) is the most widely used plastic, with an annual production of approximately 80 million metric tons. Its primary use is within packaging (plastic bag, plastic films etc.). | ||||||||||||

| Polyethylene is a thermoplastic polymer consisting of long chains produced by combing the ingredient monomer ethylene (IUPAC name ethene), the name comes from the ingredient and not the actual chemical resulting. | ||||||||||||

| The ethene molecule (known almost universally by its common name ethylene) C2H4 is CH2=CH2, Two CH2 groups connected by a double bond, thus: | ||||||||||||

|

||||||||||||

| Polyethylene is classified into several different categories based mostly on its density and branching. The mechanical properties of PE depend significantly on variables such as the extent and type of branching, the crystal structure and the molecular weight. With regard to sold volumes, the most important polyethylene grades are HDPE, LLDPE and LDPE. | ||||||||||||

|

||||||||||||

| PE WPC is used for making high density and rough applications in exteriors. PE WPC can give products like decking including flooring, lumber, moulding strips, furniture materials, wall cladding, hollow boards, hollow filler sections and profiles. |

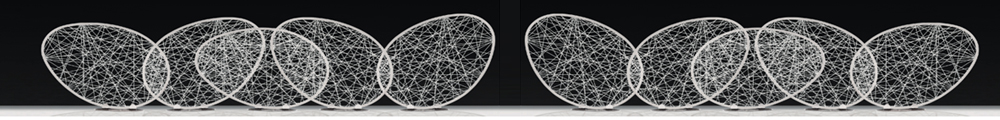

For More quality picture and product details ,please visit at http://www.modernrattanfurniture.com/Products-Information.html